Selecting the optimal refractory insulating brick for chemical furnaces operating below 1350°C involves a deep understanding of key performance criteria, including thermal conductivity, thermal shock resistance, linear shrinkage, and mechanical strength. These parameters critically influence furnace efficiency, lifespan, and maintenance costs. This article offers a comprehensive technical analysis to assist engineers and decision-makers in making informed choices that enhance furnace reliability and energy efficiency while minimizing operational risks.

Reliable furnace linings depend on a balanced combination of the following primary properties:

| Brick Type | Thermal Conductivity (W/m·K) | Thermal Shock Resistance (Cycles) | Linear Shrinkage (%) | Cold Crushing Strength (MPa) |

|---|---|---|---|---|

| High Alumina Brick | 1.5 - 2.0 | 50 - 70 | 0.5 - 1.0 | 60 - 150 |

| Ordinary Fireclay Brick | 0.7 - 1.0 | 20 - 30 | 1.5 - 2.0 | 20 - 40 |

| Hollow Sphere Brick | 0.3 - 0.5 | 25 - 40 | 0.8 - 1.2 | 25 - 50 |

| High-Strength Refractory Clay Insulating Brick (Our Product) | 0.28 - 0.35 | 75 - 90 | 0.3 - 0.6 | 55 - 80 |

The high-strength refractory clay insulating brick demonstrates superior thermal shock resistance and dimensional stability, achieving energy savings through its low thermal conductivity.

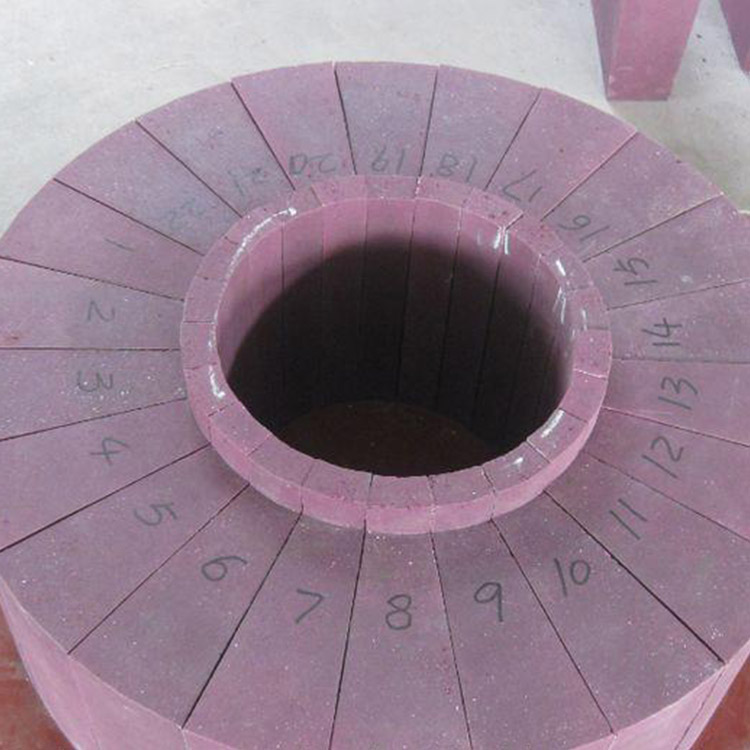

In chemical processing plants, furnaces are frequently subjected to abrupt start-stop cycles and temperature fluctuations near 1350°C. Our high-strength refractory clay insulating bricks reliably endure these thermal dynamics with minimal cracking risk. A recent engineering project at a major chemical plant recorded a 35% reduction in energy consumption and a 40% extension in maintenance intervals after replacing conventional bricks with this advanced material.

Choosing refractory bricks based solely on price often overlooks the critical importance of thermal stability and durability, resulting in premature failure and rising overall lifecycle costs. Engineering decisions must integrate a holistic evaluation of performance metrics aligned with operational demands rather than initial acquisition cost.

Experimental tests under standardized conditions confirm that high-strength refractory clay insulating bricks maintain integrity after more than 90 thermal shock cycles and show linear shrinkage consistently under 0.6%, well below competitive materials. Mechanical strength remains stable above 60 MPa post multiple heating cycles, evidencing their robustness for demanding industrial environments.

For further engineering details and tailored selection advice, download our comprehensive selection handbook here.

The synergy of low thermal conductivity and robust mechanical properties directly translates into measurable fuel savings and extends furnace lifespan. By selecting bricks optimized for chemical furnace conditions below 1350°C, facilities can achieve sustainable operational gains without compromising safety and reliability.

Explore a detailed breakdown of thermal properties and mechanical characteristics, and access expert selection assistance today.