In the competitive landscape of industrial heating processes, the demand for energy-efficient solutions has never been higher. Low thermal conductivity insulating firebricks, particularly those based on mullite technology, are becoming a cornerstone in reducing energy consumption and operational costs of high-temperature furnaces. This article explores the cutting-edge technology behind these materials, their performance advantages, and real-world applications that make them indispensable in modern industrial thermal management.

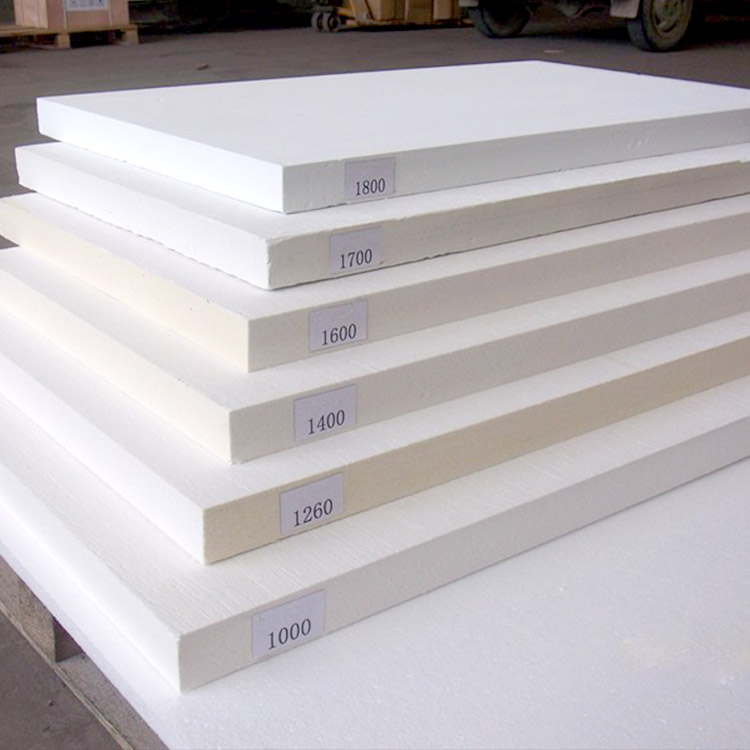

At the core of high-performance low thermal conductivity insulating firebricks lies the use of high-purity fused alumina combined with imported tabular alumina raw materials. These premium-grade minerals ensure enhanced refractory properties and thermal resistance. The incorporation of ultrafine powder additives promotes superior particle packing density and reduces material porosity, which are critical for thermal insulation and mechanical strength. This high-tech raw material combination is brought to life through a precision high-temperature shuttle kiln sintering process, allowing for exceptional dimensional control (with tolerances within ±0.2 mm) and consistent quality across production batches. This meticulous process ensures the bricks achieve optimal crystalline bonding and microstructure, resulting in enhanced durability under cyclical thermal shock stresses.

The finished mullite insulating firebrick boasts a refractory temperature exceeding 1750°C, making it suitable for extreme industrial environments. Its remarkable thermal shock resistance reduces the risk of cracking during rapid temperature fluctuations common in operational cycles, extending the service life by up to 30%-50% compared to traditional firebricks.

The ultra-precise dimensional stability facilitates quicker, more accurate furnace lining installations, accelerating construction schedules by approximately 20%. Less consumption of refractory mortar is required due to the enhanced brick fitting, leading to cost savings of roughly 15% in auxiliary materials. These combined benefits translate directly into reduced downtime and enhanced process reliability.

These insulating firebricks have been extensively applied in demanding industrial environments such as petroleum cracking furnaces and metallurgical blast furnaces. In petroleum pyrolysis units, they have contributed to a documented energy saving of 8-12% by significantly reducing heat loss through furnace walls. In metallurgy, the bricks offer substantial gains in maintaining critical high temperatures with less fuel consumption.

Additionally, the extended brick lifespan directly reduces maintenance frequency, enabling operational continuity and lowering overall furnace refurbishment costs by as much as 25%. These performance metrics are supported by field tests and customer feedback across multiple industrial retrofit projects.

Selecting the most suitable insulating firebrick hinges on matching brick properties to the specific furnace operating conditions. For instance, high thermal shock stability bricks are recommended in blast furnace bosh zones, while bricks with superior insulating properties suit recovery boilers. Proper installation techniques, such as using thin, even mortar layers and ensuring tight brick interlocks, are crucial to maximize thermal efficiency and mechanical integrity.

Furnace engineers should also consider complementary design alterations—like optimizing brick shape to minimize joints and enhancing airflow dynamics—to derive full advantage of the firebrick’s insulation potential.

Beyond tangible energy savings, these low thermal conductivity insulating firebricks contribute significantly to environmental compliance by lowering CO2 emissions associated with fuel combustion. Their longevity reduces raw material consumption for replacements, fostering sustainable operational practices. Furthermore, decreased maintenance interventions improve workplace safety by limiting furnace exposure.