In the realm of industrial production, energy conservation has always been a top - priority issue. Low thermal conductivity insulation refractory bricks have emerged as a revolutionary solution in this field. These bricks play a crucial strategic role in industrial energy conservation, as they help industries reduce energy consumption and enhance overall operational efficiency.

The core raw materials of low thermal conductivity insulation refractory bricks are high - purity fused corundum and imported tabular corundum. High - purity fused corundum has a very low impurity content, which endows the bricks with excellent high - temperature resistance. Imported tabular corundum, on the other hand, has a stable crystal structure, which significantly enhances the structural stability of the bricks. Studies have shown that bricks made with these two core raw materials can withstand temperatures up to 1800°C, far exceeding the performance of traditional refractory bricks.

The ultrafine powder addition technology is a key innovation. By adding ultrafine powders, the internal structure of the bricks becomes more compact, reducing the porosity and thus lowering the thermal conductivity. The high - temperature shuttle kiln sintering process is also crucial. It allows for precise control of the sintering temperature and time, ensuring that the bricks achieve optimal physical and chemical properties. For example, through this process, the thermal conductivity of the bricks can be reduced to 0.2 - 0.3 W/(m·K), while traditional bricks usually have a thermal conductivity of 0.5 - 0.8 W/(m·K). A comparison chart of thermal conductivity between low thermal conductivity insulation refractory bricks and traditional bricks is as follows:

| Brick Type | Thermal Conductivity (W/(m·K)) |

|---|---|

| Low Thermal Conductivity Insulation Refractory Bricks | 0.2 - 0.3 |

| Traditional Bricks | 0.5 - 0.8 |

As mentioned earlier, these bricks can resist high temperatures up to 1800°C, which makes them suitable for use in high - temperature industrial furnaces such as steelmaking furnaces and glass melting furnaces.

They can withstand rapid temperature changes without cracking or spalling. Tests have shown that they can endure at least 50 thermal shock cycles from room temperature to 1000°C, ensuring long - term stable operation in industrial furnaces.

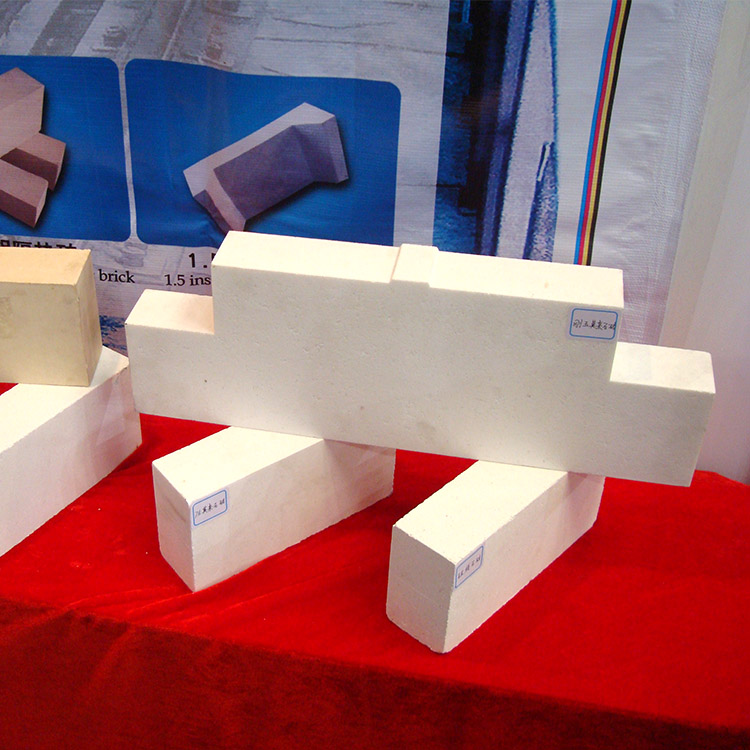

The precise dimensions of these bricks reduce the time and labor required for masonry. The dimensional tolerance is controlled within ±0.5mm, which is much more accurate than traditional bricks.

In real - world applications, such as in oil cracking kilns and tunnel kilns, low thermal conductivity insulation refractory bricks have demonstrated remarkable energy - saving effects. In an oil cracking kiln, the use of these bricks can reduce heat loss by 30 - 40%, and at the same time, extend the furnace lining life by 2 - 3 times. For example, a certain oil refinery replaced traditional refractory bricks with low thermal conductivity insulation refractory bricks in its cracking kiln. After the replacement, the energy consumption decreased by 35%, and the maintenance cycle of the furnace lining was extended from 1 year to 3 years.

When selecting low thermal conductivity insulation refractory bricks, factors such as the operating temperature, thermal shock requirements, and chemical environment of the industrial furnace should be considered. Here are some common questions and answers to help you make a more informed decision:

If you are interested in learning more about our low thermal conductivity insulation refractory bricks, immediately obtain the product technical manual or contact our engineers to get a customized solution.