In the highly energy-intensive process of petrochemical cracking, selecting the appropriate refractory materials plays a pivotal role in enhancing furnace efficiency, reducing energy consumption, and extending operational lifespan. This article delves into the advantages of low thermal conductivity insulating refractory bricks specifically engineered for petrochemical cracking furnaces, highlighting how innovations in material composition and manufacturing processes translate into tangible operational benefits.

The foundation of superior insulating refractory bricks lies in the choice of raw materials. Utilizing high-purity fused corundum combined with imported tabular alumina provides exceptional refractory properties such as high alumina content typically exceeding 99.5%, which ensures a melting point above 1850°C. These materials exhibit minimal impurities, translating into enhanced chemical stability and abrasion resistance under high-temperature cracking furnace conditions.

Additionally, incorporating ultrafine powders during the mix formulation facilitates a denser microstructure post-sintering. This increases the brick’s intrinsic thermal insulation capacity, as ultrafine particles minimize pore connectivity, resulting in a decreased thermal conductivity often ranging between 0.5 to 0.8 W/m·K at 1000°C—substantially lower than traditional fireclay bricks.

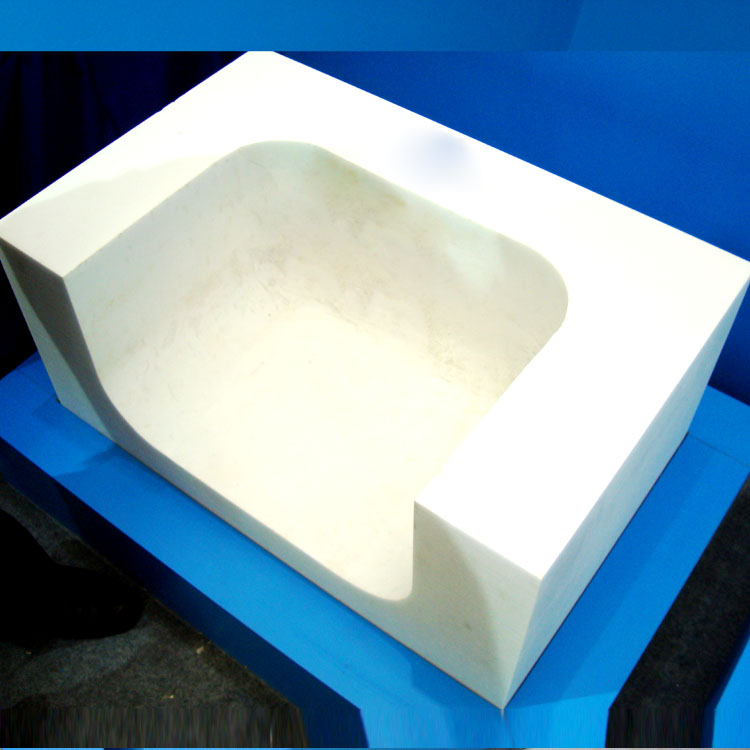

Beyond raw materials, the manufacturing process critically affects the performance of insulating bricks. Employing a high-temperature shuttle kiln allows precise temperature control and uniform heating cycles essential for consistent sintering. This method reduces microcracks and warping, producing bricks with tight dimensional tolerances (±0.5 mm), crucial for efficient furnace lining assembly and minimizing gaps that can cause thermal leakage.

The resultant refractory bricks demonstrate a high refractoriness exceeding 1780°C and outstanding thermal shock resistance withstanding rapid temperature fluctuations typical in cracking furnace operations. These properties reduce the frequency of repairs or replacements, lowering unplanned downtime and maintenance costs.

Moreover, accurate sizing boosts installation efficiency by ensuring easier fitting and alignment with existing linings, enhancing mechanical stability. This leads to better structural integrity and improved heat retention, with documented heat loss reductions up to 25% compared to conventional insulating bricks.

Real-world applications in petrochemical cracking furnaces show that implementing these advanced insulating bricks extends furnace lining lifespans by 20–30%, markedly reducing replacement frequency. One industrial user reported a 15% gain in thermal efficiency, correlating with energy savings of approximately 200,000 kWh annually.

Similar improvements are observed in other industrial kilns such as metallurgical blast furnaces, where maintaining stable high temperatures with minimal thermal losses critically impacts output quality and fuel consumption.

When considering refractory material upgrades, users should evaluate furnace operating temperatures, thermal cycling frequency, and installation conditions. Incorporating low thermal conductivity bricks with optimized alumina content and precise dimensions can significantly improve thermal management.

For retrofit projects, combining these bricks with existing castable refractories in critical zones can maximize energy conservation while maintaining necessary mechanical strength. Cooperation with technical suppliers for customized solutions and on-site support ensures optimal performance and return on investment.