Industrial furnaces are the backbone of energy-intensive sectors like petrochemicals, steelmaking, and ceramics. Yet many still operate with outdated refractory materials that compromise efficiency, safety, and lifespan. At our core, we engineer low thermal conductivity insulating firebrick—specifically designed to solve these real-world challenges.

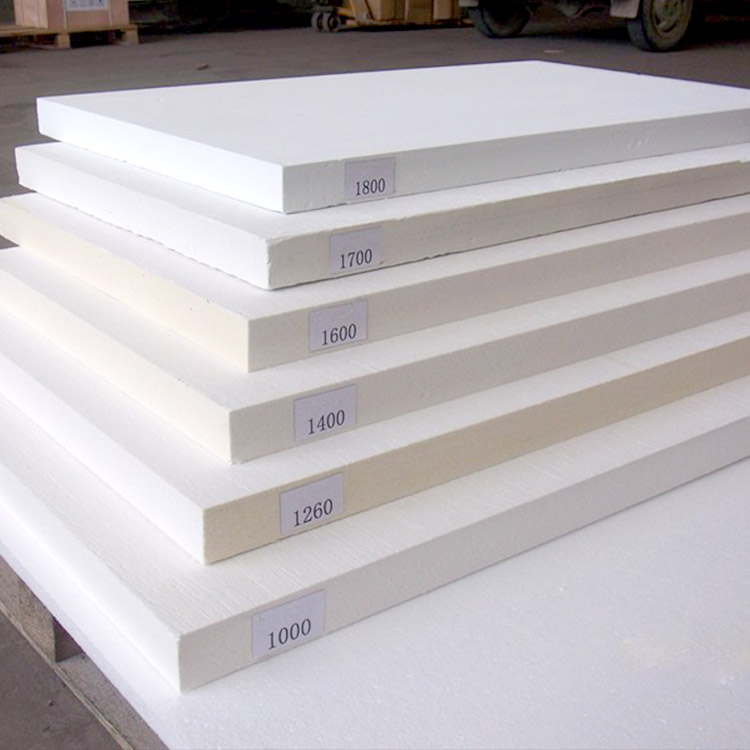

Our advanced insulation bricks use high-purity fused alumina (Al₂O₃ ≥ 99%) and imported tabular alumina as raw materials. These aren't just "good enough"—they're selected for their exceptional purity, which minimizes impurities that degrade performance at high temperatures. Combined with nano-scale powder additives and a precision sintering process in a shuttle kiln (up to 1750°C), the result is a material with:

These properties directly translate into better furnace liner stability, reduced thermal stress, and faster installation times due to precise dimensional control (±0.5 mm tolerance).

In a recent case study with a major oil refinery in Saudi Arabia, replacing traditional insulating bricks with our low-conductivity solution led to:

“A 12% reduction in fuel consumption over six months, with zero downtime related to liner failure.”

Similarly, in a Chinese steel plant, using this brick in blast furnace hot blast stoves extended lining life from 18 months to over 36 months—cutting maintenance costs by nearly 40% annually.

What makes this material stand out isn’t just its specs—it’s how it integrates seamlessly into existing systems while delivering measurable ROI. Whether you’re optimizing an existing furnace or designing a new one, choosing the right refractory can mean the difference between marginal operation and peak efficiency.

If you're evaluating materials for your next project, consider:

Don’t guess—engineer your choice. We offer free technical consultations tailored to your application, including customized installation plans and long-term lifecycle cost analysis.

Get expert guidance on selecting the right low-conductivity insulating firebrick for your needs—from design to installation.

Download Our Refractory Selection Guide