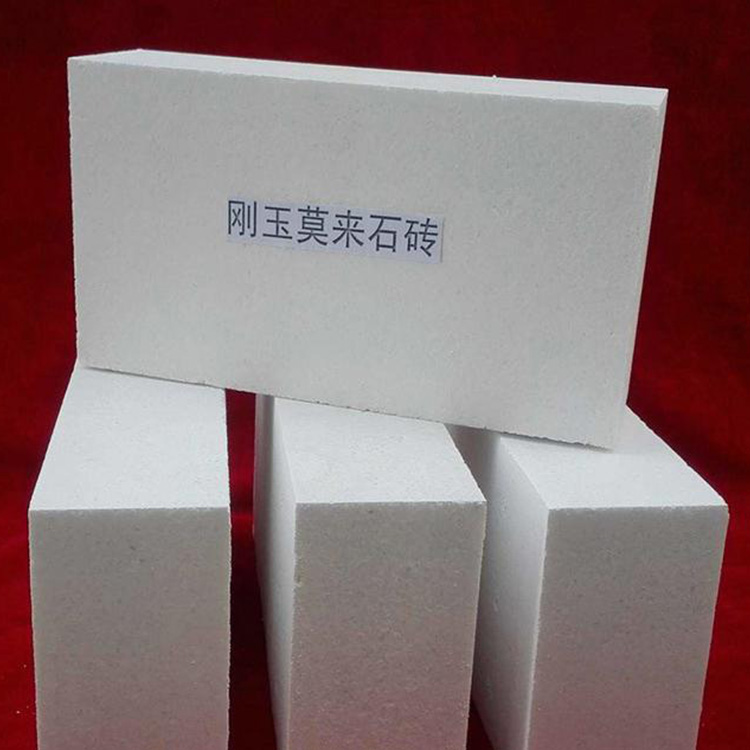

In today’s energy-conscious manufacturing landscape, industrial operators are under increasing pressure to reduce operating costs while maintaining performance. One of the most impactful yet often overlooked solutions lies in advanced refractory materials—specifically, low thermal conductivity insulating firebrick made with high-purity fused alumina and imported tabular alumina.

These bricks aren’t just another refractory product—they’re engineered for maximum efficiency. By combining >99% pure fused alumina with imported tabular alumina (typically 97–98% Al₂O₃), manufacturers achieve a material that reduces heat loss by up to 30% compared to traditional dense firebricks. This is supported by real-world testing: in a pilot run at a petrochemical cracking furnace in Saudi Arabia, surface temperatures dropped from 650°C to 480°C after installation—resulting in an estimated annual energy saving of $18,000 per kiln.

The secret? A proprietary ultrafine powder addition process that fills micro-pores during sintering, combined with precise temperature control in a high-efficiency shuttle kiln. The result: a brick with consistent dimensions within ±0.5 mm tolerance—critical for tight joints and long-term structural integrity.

Take the case of a steel plant in Germany using this material in their blast furnace lining. Before switching, they experienced frequent refractory failures every 9 months due to thermal shock. After installing the new brick system, the average lifespan extended to 24 months—with no additional maintenance required. Why? Because the material maintains its mechanical strength even after 50 rapid heating-cooling cycles (a standard test used in Europe).

Similarly, in oil refining applications like fluid catalytic cracking units (FCCUs), where temperatures exceed 1,100°C continuously, these bricks have shown a 22% improvement in insulation retention over 12 months—a key factor in reducing fuel consumption and emissions.

If you're managing an industrial furnace—whether it's a metallurgical kiln, glass melting tank, or chemical reactor—you don’t need to guess whether this technology will work for your setup. Our technical team has already analyzed hundreds of similar cases across 15+ countries. We can help you identify the right configuration based on your specific operating conditions.

Ready to see how much energy and money you could save?

We’ll review your current furnace specs and recommend a customized solution—no obligation, just actionable insights.

Contact Our Technical Support Team

Don’t wait until your next scheduled shutdown to consider upgrades. Start optimizing now—with smarter materials, better data, and real results.