In today’s energy-conscious industrial landscape, optimizing furnace performance isn’t just about productivity—it’s about sustainability. One of the most impactful upgrades companies can make is switching to high-performance insulating refractory bricks with low thermal conductivity. Our latest case studies from petroleum cracking kilns and blast furnaces demonstrate how this material innovation delivers measurable savings in fuel consumption, extended lining life, and improved operational stability.

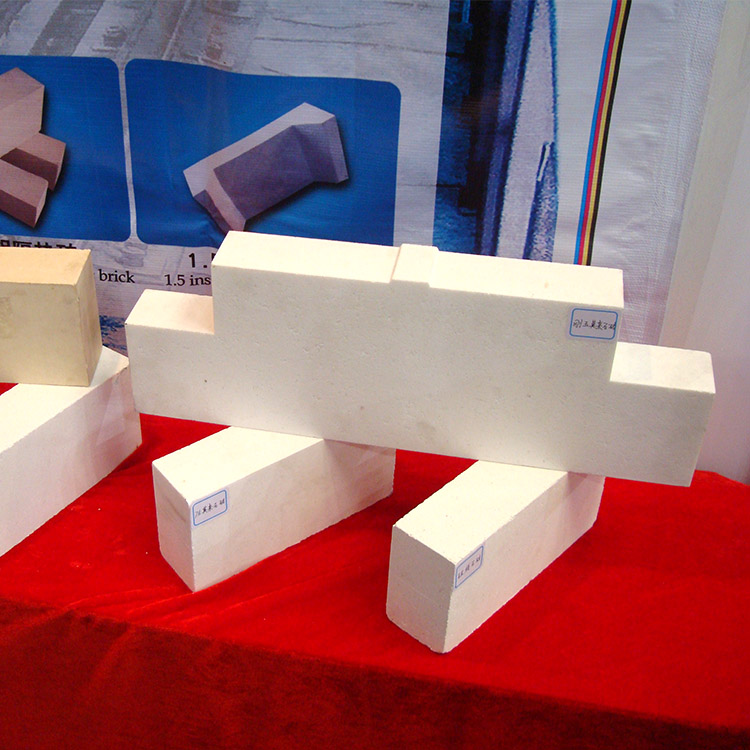

These bricks are engineered using a blend of high-purity fused alumina (≥99.5%) and imported tabular alumina—both known for exceptional chemical stability and resistance to thermal shock. By incorporating ultra-fine powder additives and firing in a precision-controlled high-temperature shuttle kiln at 1750°C, we achieve consistent microstructure uniformity across every brick. This results in:

A major petrochemical plant in Saudi Arabia replaced their old insulation layer in a coking unit with our low-conductivity bricks. Within six months:

Similarly, a steel mill in Germany reported similar gains after installing these bricks in their blast furnace hot face lining. Their average temperature gradient across the wall reduced by 120°C, leading to more stable operation and fewer maintenance interruptions.

Whether you're managing a refinery, smelter, or cement kiln, inefficient heat retention means wasted money—and missed opportunities. These bricks don't just reduce costs—they enhance safety, improve process consistency, and support ESG goals through lower CO₂ emissions per unit of output.

For engineers, procurement managers, and plant operators looking to upgrade their refractory systems, it's time to move beyond generic solutions. The data speaks clearly: better materials = smarter operations.

Get expert guidance on selecting the right insulating refractory bricks for your application—based on real-world performance data and tailored technical support.

Explore Product Specifications & Technical Support