Thermal Expansion Matching Techniques for Industrial Furnaces: Preventing Refractory Interface Spalling

2025-12-21

Tutorial Guide

This article delves into thermal expansion matching strategies specifically for high-alumina insulating bricks in industrial furnace applications. It thoroughly analyzes three prevalent challenges in refractory selection: insufficient thermal shock resistance, prolonged exposure beyond maximum service temperature, and improper thermal expansion compatibility leading to interface spalling. By exploring the primary crystal phases of high-alumina bricks, such as mullite and corundum, alongside practical examples of multi-layer brick configurations, this guide offers actionable self-inspection methods including surface network crack and spalling pattern identification. Targeted at production and technical personnel in steel, ceramic, and petrochemical high-temperature equipment sectors, the content aims to support furnace life extension and energy efficiency through scientific maintenance and failure prevention.

Industrial Furnace Thermal Expansion Matching: Preventing Refractory Interface Delamination

In high-temperature industrial applications such as steel manufacturing, ceramics, and petrochemicals, the reliability of refractory linings is critical. Among numerous factors, the precise matching of thermal expansion coefficients of refractory materials is a decisive factor in preventing interface delamination. This article delves into effective matching techniques for high alumina insulation bricks used in industrial furnaces, addressing key challenges like insufficient thermal shock resistance, temperature limits exceedance, and thermal expansion mismatches that lead to refractory failures.

Key Challenges in Refractory Material Selection

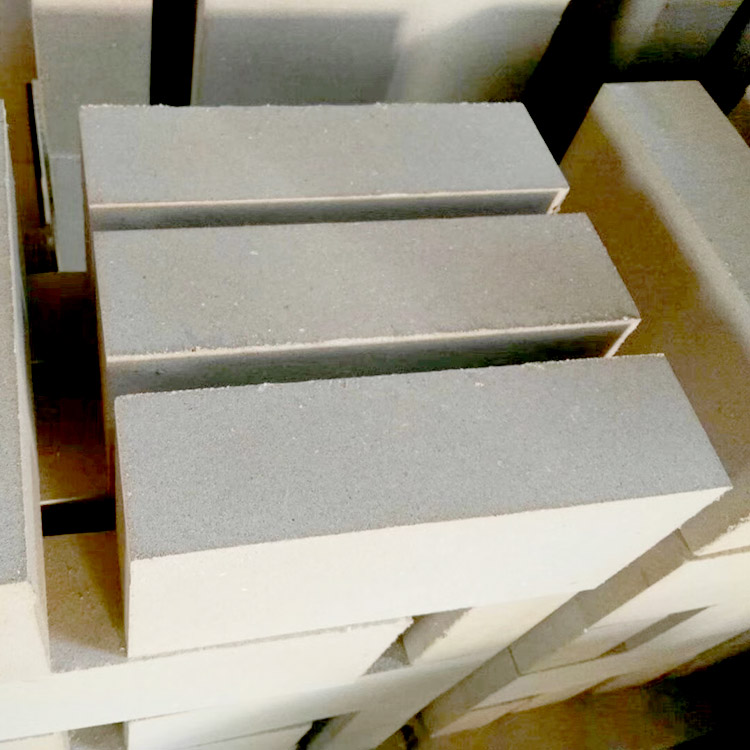

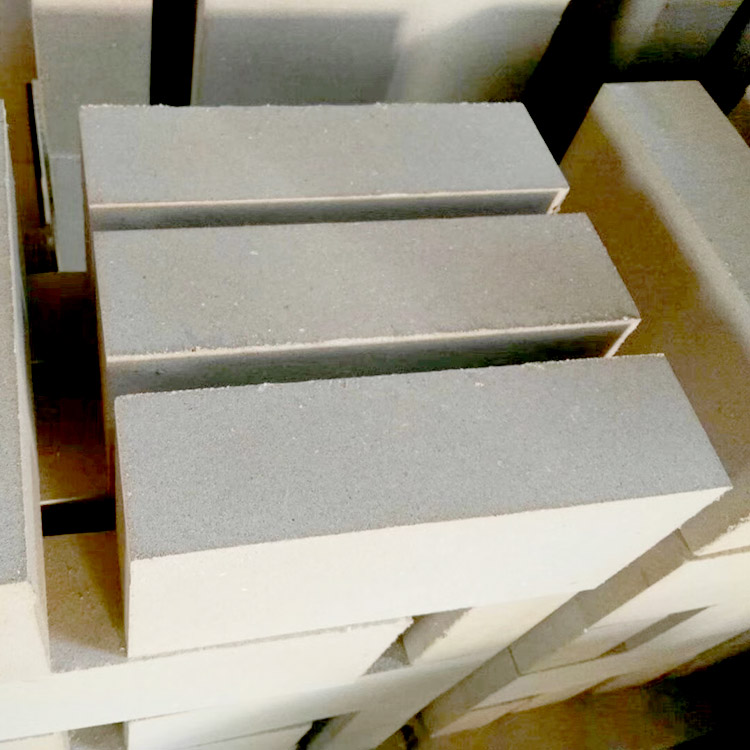

High alumina bricks, predominantly comprising mullite (3Al2O3·2SiO2) and corundum (α-Al2O3) phases, offer outstanding high-temperature stability. However, several technical obstacles must be controlled:

- Thermal shock resistance: Rapid temperature fluctuations can cause microcracking. Bricks with a mismatch in expansion coefficients amplify internal stresses.

- Long-term operating temperature: Surpassing the continuous use temperature (typically 1400-1600°C for high alumina bricks) accelerates grain growth and weakens mechanical integrity.

- Thermal expansion mismatch: Differences in expansion rates between brick layers or between bricks and metal parts cause interface stress, leading to delamination or spalling.

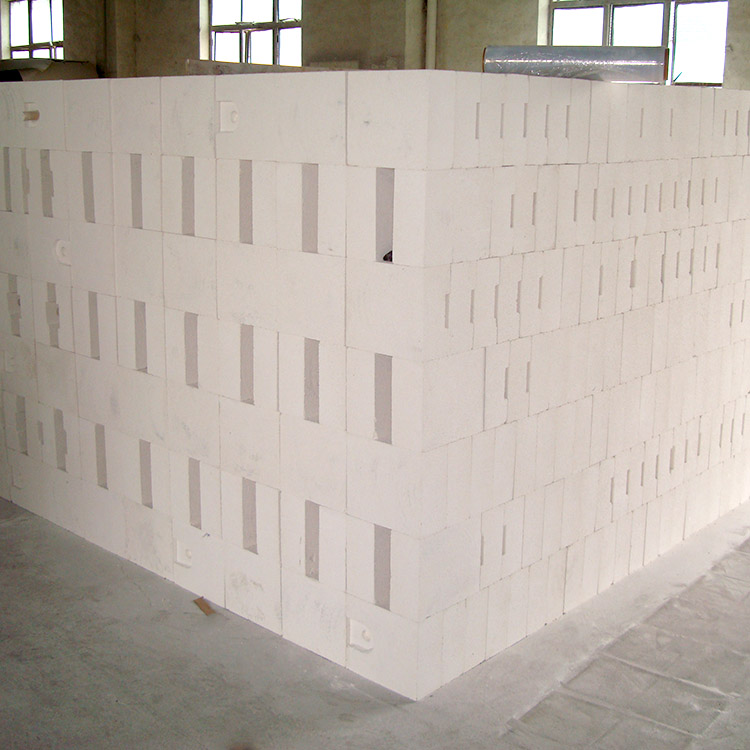

Optimized Multi-layer Brick Configuration for Enhanced Performance

Implementing a rational arrangement of refractory bricks improves thermal expansion compatibility and extends furnace lifespan. For instance, a typical layout for steel industry furnaces might include:

- Innermost layer: Dense corundum bricks (thermal expansion ~ 7.5 x 10-6/K) for superior abrasion resistance.

- Intermediate insulation layer: High alumina insulation bricks with balanced thermal expansion (8-9 x 10-6/K) to reduce heat transfer and suppress thermal gradients.

- Outer protective layer: Fireclay or carbon bricks designed for moderate thermal expansion to buffer mechanical impacts.

Such gradation aligns thermal expansion rates, mitigating interface stresses effectively. Laboratory tests show that well-matched layers can reduce crack propagation by over 40%, significantly curbing premature refractory failure.

Practical Diagnostic Techniques to Assess Thermal Expansion Compatibility

Effective on-site evaluation enables maintenance teams to detect early signs of thermal mismatch and intervene before safety risks escalate. Key indicators include:

- Network-like microcracks on brick surfaces: Initial thermal stress often manifests as spiderweb cracking patterns detectable by visual inspection or ultrasonic testing.

- Exfoliation or delamination traces: Slight brick peeling near interfaces signals differential thermal strains exceeding material limits.

Routine use of thermal imaging and acoustic emission monitoring enhances predictive maintenance capabilities, allowing optimization of service intervals and reducing unplanned shutdowns.

Case Highlight: Steel Industry Application

In a leading steel plant, replacing poorly matched refractory bricks with a tailored high alumina multi-layer configuration resulted in a remarkable 18% increase in furnace campaign life and a 12% improvement in fuel efficiency. This directly contributed to lower production costs and reduced downtime for maintenance.

Engineering teams emphasize that selecting refractory materials certified to international standards and tested for thermal expansion compatibility is a prerequisite for achieving consistent furnace performance in high-temperature operations.

Ensuring Long-Term Furnace Reliability Through Expert Material Selection

Maximizing the operational lifespan of industrial furnaces requires a strategic approach to refractory material selection and thermal expansion matching. Engineering guidelines recommend:

- Performing detailed thermal expansion coefficient measurements of candidate materials under actual service conditions.

- Incorporating multi-layer refractory designs tailored to specific furnace types and process temperatures.

- Implementing regular diagnostic inspections to detect early thermal stress damage.

- Prioritizing products that comply with international refractory quality certifications (ISO 14001, ISO 9001).

Discover High-Quality High Alumina Insulation Bricks with Certified Thermal Expansion Compatibility & Energy Saving Benefits