In industrial furnace applications, energy efficiency and durability are paramount. Imported tabular corundum insulating bricks, primarily manufactured using high-purity fused corundum and tabular alumina, combined with advanced ultrafine powder additives and precision sintering via high-temperature shuttle kiln processes, have emerged as the forefront solution for industrial refractory challenges. Their superior refractory properties significantly reduce thermal conduction losses, improve heat retention, and extend service life, driving factories worldwide to adopt these cutting-edge materials.

The core raw materials — imported tabular corundum and fused corundum with purity levels exceeding 99.5% — ensure extremely high refractoriness (>1780°C), giving bricks excellent resistance to extreme thermal environments. The introduction of ultra-fine powder additives improves particle packing density and sintering behavior, enhancing mechanical strength without sacrificing insulation properties.

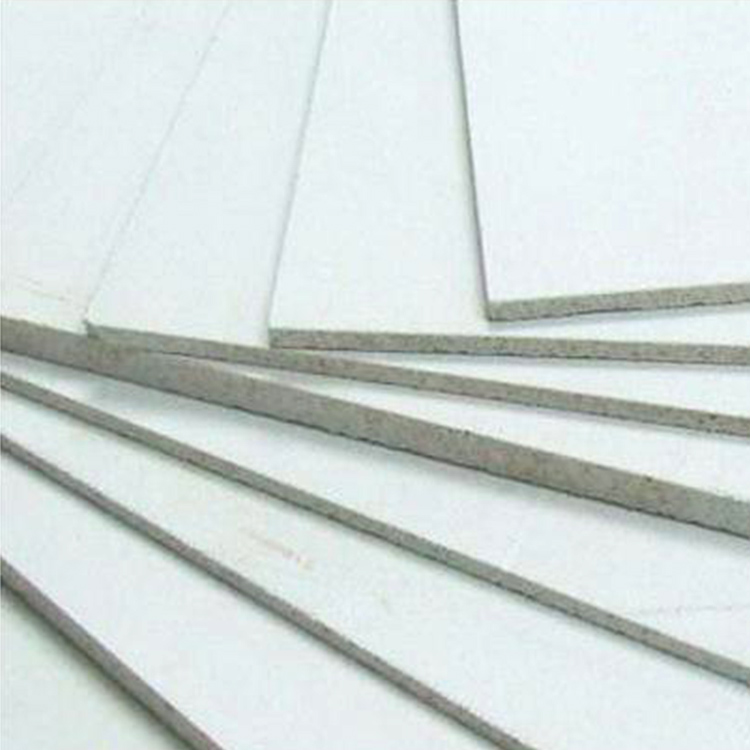

Precision manufacturing using high-temperature shuttle kilns allows for uniform sintering and tightly controlled microstructures. This process produces insulating bricks with low thermal conductivity (typically 0.15 - 0.25 W/m·K at 1000°C), outstanding thermal shock resistance (retaining >85% strength after 10 cycles of 1350°C heat shock), and dimensional accuracy within ±0.3 mm, facilitating rapid and stable brickwork.

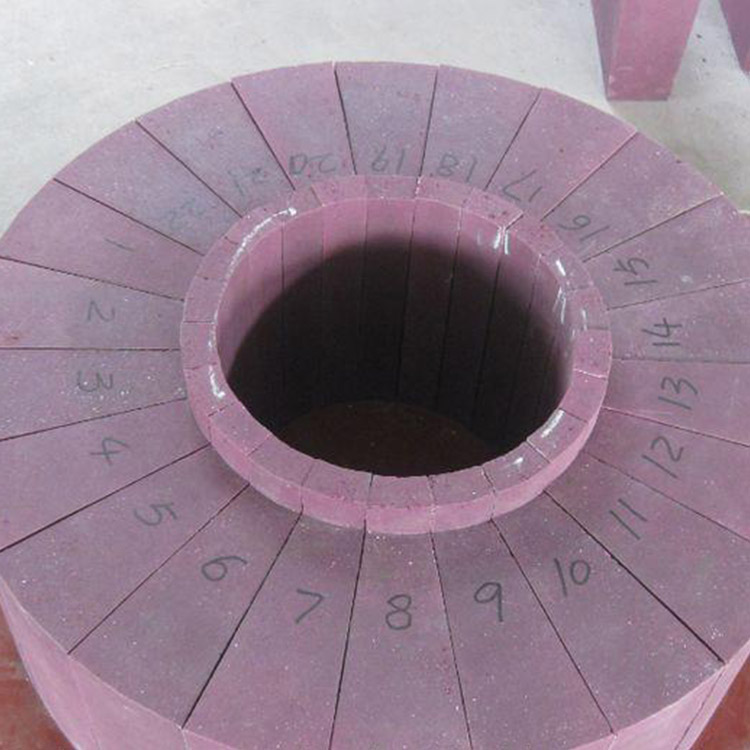

The precisely controlled dimensions and smooth rectangular shape of tabular corundum insulating bricks enable quicker installation with minimal gaps. This promotes a denser furnace lining structure, reducing cold joints that commonly cause premature failures. The bricks’ high thermal shock resistance also buffers against rapid temperature changes during furnace start-up and shutdown cycles, ultimately lowering maintenance costs and downtime.

In addition, reduced heat transfer through these bricks aligns with global initiatives toward industrial energy conservation, contributing to significant fuel savings and sustainable operations.

Consider the example of petroleum cracking furnaces operating at continuous temperatures of 1350°C. Replacing conventional insulating bricks with imported tabular corundum ones has shown a reduction in energy consumption by up to 18%, with refractory lining lifespans extended from 18 months to over 30 months. This improvement translates into substantial operational savings and fewer unplanned shutdowns.

Another case in metallurgical blast furnaces saw run-time increases of 25%, attributed to superior thermal shock resistance and stable structure integrity. Such performance benchmarks underscore the cost-effectiveness and reliability gains possible through adopting these advanced refractory materials.

When selecting insulating bricks for industrial furnaces, key considerations include operating temperature, thermal cycling frequency, mechanical load, and anticipated service life. Imported tabular corundum insulating bricks fit best where high-temperature resistance and thermal shock stability are critical.

It is advisable that engineers collaborate closely with suppliers to tailor bricks’ specifications—such as density, shape, and nominal sizes—to specific furnace designs. Installation using compatible refractory mortars and proper curing further maximizes overall performance.