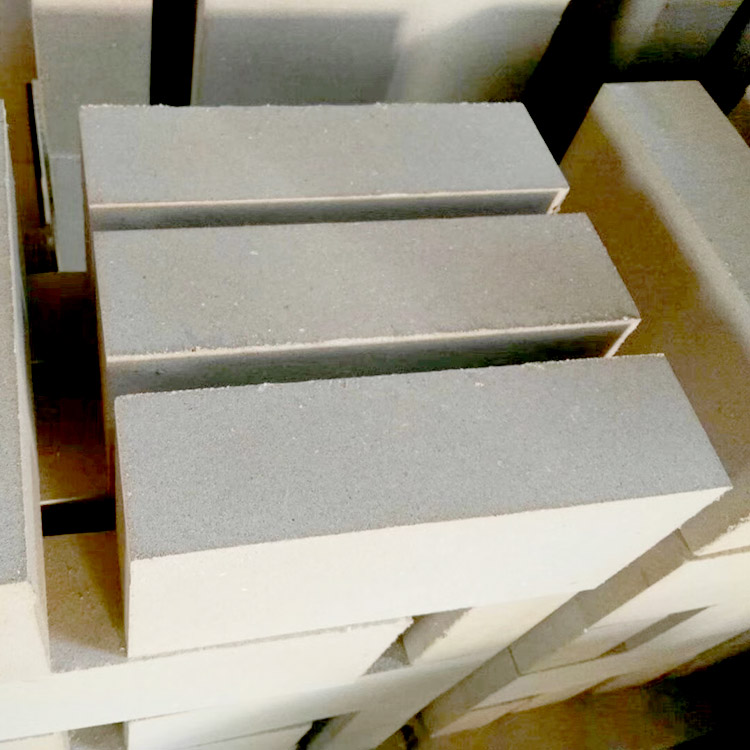

In today’s energy-conscious manufacturing landscape, optimizing furnace performance isn’t just about saving costs—it’s about staying competitive. That’s where our high-strength insulating firebrick, engineered with imported board-alumina and high-purity fused alumina, comes in. This isn’t just another refractory product—it’s a strategic upgrade for kilns, reactors, and blast furnaces worldwide.

Our bricks achieve a maximum service temperature of 1750°C (3182°F), significantly outperforming conventional dense firebricks that typically max out at 1600°C. Thanks to ultra-fine powder additives and a high-temperature shuttle kiln sintering process, the material structure is denser yet more thermally efficient—reducing heat loss by up to 30% compared to standard options.

Each brick is manufactured within ±0.5mm tolerance—a level of precision rarely seen in the industry. This means:

At a petrochemical plant in Saudi Arabia, replacing traditional bricks with our insulating solution led to a 12% drop in fuel consumption across their coking ovens within six months. In South Korea, a steel mill reported a 25% increase in lining lifespan after switching to this product in their blast furnaces—cutting downtime and maintenance costs dramatically.

These aren’t isolated cases—they reflect what happens when you combine science, precision, and real-world application. Whether you're managing a petroleum cracker or a glass melting tank, this brick delivers measurable ROI through consistent thermal efficiency and reduced operational risk.

The future of industrial heating is smarter—not just hotter. With proven results from global clients and continuous R&D support, we’re not just selling bricks—we’re helping industries evolve.