The chemical industry’s high-temperature furnaces and kilns are historically among the largest energy consumers, often accounting for over 30% of a facility's total energy expenditure. Reducing thermal losses through advanced refractory materials is a crucial step toward sustainable operations and achieving carbon footprint goals.

High-temperature furnace systems in chemical plants typically operate above 1200°C, where heat loss via refractory linings can exceed 20% of total fuel consumption. This inefficiency not only escalates operational costs but also contributes significantly to CO2 emissions. Traditional refractory bricks often lack optimized insulation properties and resistance to thermal cycling, leading to frequent maintenance and shorter service life.

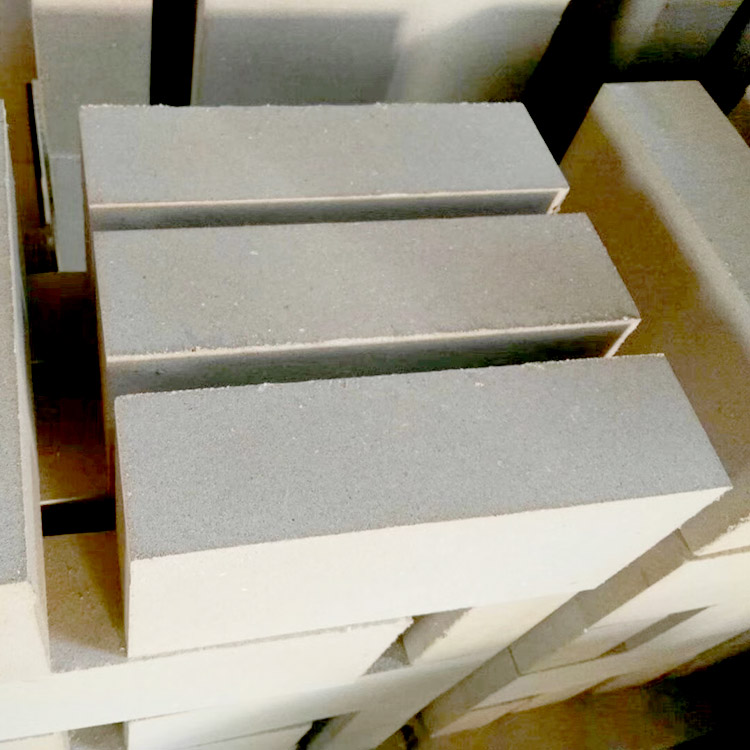

High-strength insulating fire clay bricks are engineered specifically to exhibit exceptionally low thermal conductivity—measured as low as 0.17 W/m·K at 800°C—significantly reducing heat flux through furnace linings. Their unique porous microstructure accommodates thermal expansion and improves resistance to heat shocks. With thermal shock resistance values exceeding 100 cycles, these bricks maintain structural integrity in fluctuating temperature environments.

| Property | Value | Benefit |

|---|---|---|

| Thermal Conductivity @ 800°C | 0.17 W/m·K | Minimizes heat loss, improves energy efficiency |

| Compressive Strength | ≥15 MPa | Ensures structural reliability under heavy loads |

| Thermal Shock Resistance | ≥100 cycles | Prevents cracking, extends service life |

Frequent thermal cycling during furnace startup, operation, and shutdown can cause refractory bricks to crack or spall if they lack robust thermal shock resistance. The tested high-strength insulating fire clay bricks maintain dimensional stability through rapid temperature changes, directly contributing to a reduction in unscheduled downtimes and maintenance costs. Industry reports indicate a 25% increase in refractory service lifetime after employing these bricks.

Precise installation techniques are critical to fully realize the thermal efficiency of insulating bricks. Key factors include:

Engineering supervisors recommend systematic quality checks during installation to confirm adherence to these parameters, which elevate overall system efficiency by up to 15%.

A mid-sized chemical manufacturing facility retrofitted its aging furnace linings with the described high-strength insulating fire clay bricks. Over an 18-month monitoring period, the plant recorded a 22% reduction in furnace fuel consumption, equivalent to savings of approximately 450 tonnes of CO2 emissions annually. Additionally, refractory maintenance shutdown frequency decreased by 30%, boosting production uptime.

Integrating advanced insulating refractory bricks forms a cornerstone for green manufacturing strategies. The reduction in thermal losses not only optimizes energy use but enhances process stability—a key factor in minimizing waste and emissions. This aligns perfectly with global sustainability standards such as ISO 50001 Energy Management and supports ambitious industry targets for net-zero emissions.

Discover how high-performance insulating fire clay bricks can transform your furnace operations while advancing your corporate sustainability commitments. Explore product specifications and contact our technical sales team today to revolutionize your thermal management and reduce carbon footprint efficiently.