Chemical furnaces often face severe thermal stresses that cause refractory bricks to crack, compromising equipment safety and inflating maintenance costs. This article delves into the root causes of refractory brick failure—particularly rapid temperature fluctuations, uneven heating, and intrinsic material defects—and explores how innovative hollow sphere structures combined with advanced clay formulations significantly elevate thermal shock resistance.

Thermal shock in refractory bricks arises mainly from rapid temperature variations and spatial temperature gradients within the furnace lining. For instance, temperature changes exceeding 200°C within minutes can induce tensile stresses that exceed the brick’s fracture toughness, leading to microcracks and eventually visible cracks. Uneven heating amplifies these stresses, making localized zones more prone to damage. A study by the International Journal of Refractory Materials indicates that up to 65% of refractory failures in chemical furnaces are attributed to thermal shock, posing significant safety risks and reducing service life by an average of 30%.

| Thermal Shock Parameter | Effect on Refractory Brick | Estimated Impact |

|---|---|---|

| Rapid Temperature Change (ΔT > 200°C in 5 min) | Induces tensile stress causing micro-cracks | Service life reduction up to 25% |

| Non-uniform Heating Zones | Localized thermal strain and crack initiation | 40% increased failure probability |

| Material Internal Defects | Stress concentration points across brick matrix | Accelerated crack propagation |

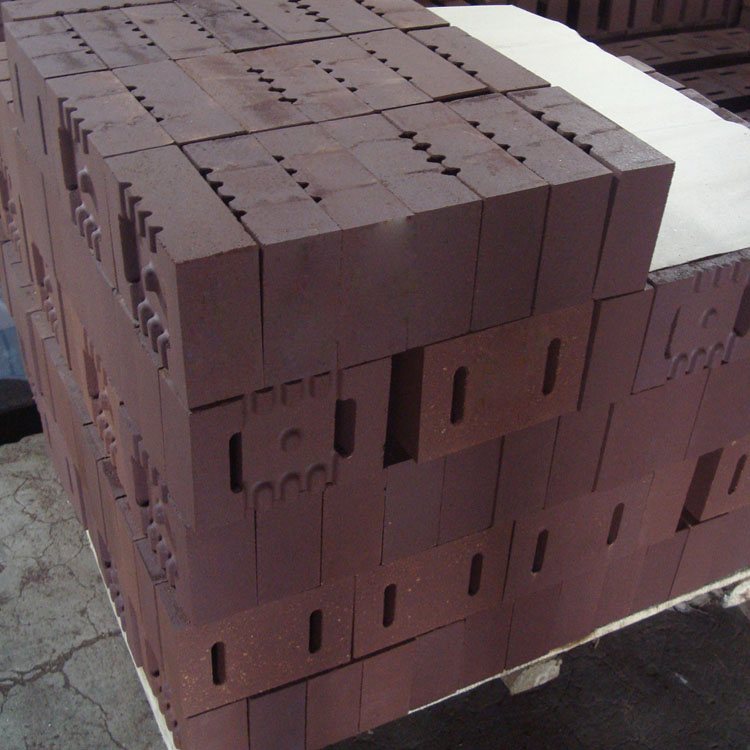

The incorporation of hollow ceramic spheres within refractory bricks introduces controlled porosity and elastic buffer zones that absorb and redistribute thermal stresses during rapid temperature shifts. Hollow spheres act as micro-expansion chambers, mitigating tensile strain and crack formation. Laboratory testing reveals that refractory bricks with a 15% volume fraction of hollow spheres exhibit up to a 45% increase in thermal shock resistance compared to traditional dense bricks.

The hollow spheres also reduce thermal conductivity by approximately 12%, contributing to more uniform temperature gradients inside the furnace lining. This design advancement not only extends brick lifespan but also lowers energy consumption by enhancing furnace insulation efficiency.

Complementing the hollow sphere structure, specialized high-purity clay formulations rich in alumina and silica are critical for strengthening refractory matrix bonding and limiting porosity variability. Such advanced clay compositions improve mechanical strength by 20% and reduce microdefects that otherwise act as crack nucleation sites under thermal cycling.

When combined with the hollow spheres, this formulation delivers a synergistic effect: enabling the brick to resist tensile stresses while maintaining structural integrity over long operational cycles exceeding 12 months without significant degradation.

Effective thermal stress management extends beyond material innovation. Routine inspection practices are paramount for operational safety. Key indicators include:

Implementing these strategies enables maintenance teams to intervene before minor defects escalate into critical failures, thereby safeguarding costly chemical furnace operations and optimizing maintenance budgets.

Discover how high-strength refractory bricks featuring advanced hollow sphere structures and premium clay formulations can revolutionize your furnace’s thermal shock resilience—Explore Our Expert-Engineered Thermal Resistant Bricks Today.