In the current industrial landscape, energy conservation and efficiency improvement are of paramount importance. Low - thermal conductivity insulating refractory bricks have emerged as a revolutionary solution in the fields of petroleum cracking kilns and metallurgical blast furnaces. This article delves into the application of these bricks in energy - saving scenarios, exploring their core technologies, performance advantages, and real - world case studies.

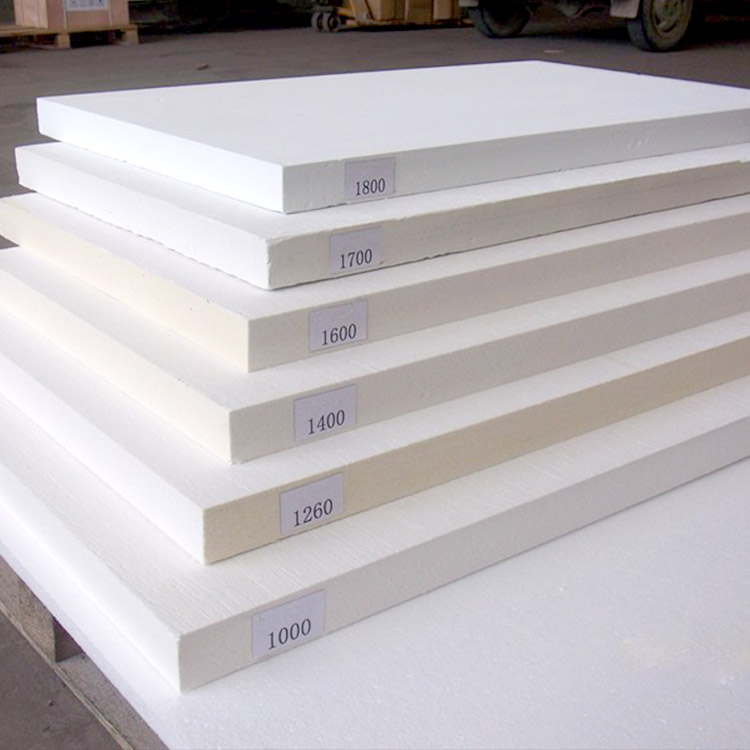

The low - thermal conductivity insulating refractory bricks are made from high - purity fused corundum and imported tabular corundum. These materials provide a solid foundation for the excellent performance of the bricks. The use of high - purity fused corundum, with a purity of up to 99%, offers high refractoriness and chemical stability. The imported tabular corundum, on the other hand, enhances the density and strength of the bricks.

In addition to the superior raw materials, an advanced ultrafine powder addition technology is employed. This technology allows for a more uniform distribution of the raw materials, improving the overall quality of the bricks. Moreover, the high - temperature shuttle kiln precision sintering process ensures that the bricks have a stable crystal structure, which is crucial for their long - term performance.

These refractory bricks boast several outstanding performance advantages. Firstly, they have a high refractoriness, with a melting point of over 2000°C, which enables them to withstand the extreme temperatures in petroleum cracking kilns and metallurgical blast furnaces. Secondly, their excellent thermal shock stability allows them to resist sudden temperature changes without cracking or spalling. This is particularly important in industrial applications where temperature fluctuations are common.

The precise brick dimensions also contribute to their performance. With a dimensional accuracy of ±0.5mm, these bricks can be quickly and easily installed, reducing the construction time and improving the overall structural stability of the furnace lining. This not only saves labor costs but also ensures a more reliable operation of the kiln or furnace.

Let's take a look at some real - world case studies to see how these low - thermal conductivity insulating refractory bricks have made a difference. In a petroleum cracking kiln in a large - scale petrochemical plant, after replacing the traditional refractory bricks with our low - thermal conductivity insulating refractory bricks, the heat loss was reduced by 30%. This led to a significant reduction in energy consumption, saving the plant approximately 10% of its annual energy costs.

In a metallurgical blast furnace, the use of these bricks extended the furnace lining life from 2 years to 3 years. This not only reduced the frequency of furnace repairs but also increased the overall production efficiency. The furnace was able to operate at a higher capacity, resulting in a 15% increase in output.

When selecting low - thermal conductivity insulating refractory bricks, several factors need to be considered. These include the operating temperature, thermal shock resistance requirements, and the chemical environment of the kiln or furnace. Our technical team can provide professional guidance based on your specific needs.

In terms of application, proper installation and maintenance are crucial. We recommend following our detailed installation instructions and conducting regular inspections to ensure the long - term performance of the bricks.

Are you looking to optimize the energy efficiency of your industrial kilns or furnaces? Our low - thermal conductivity insulating refractory bricks offer a proven solution. Contact our technical support team at CTA - URL to learn more about our products and how they can benefit your business.