In the industrial sector, the choice of refractory materials and proper masonry techniques play a crucial role in the performance and longevity of kilns. Mullite insulation bricks have emerged as a reliable solution for various high - temperature industrial kilns. This article will comprehensively analyze the application scenarios and masonry skills of mullite insulation bricks, aiming to help technical and maintenance personnel in overseas kiln projects optimize kiln structures, enhance operational safety and efficiency, and reduce maintenance costs.

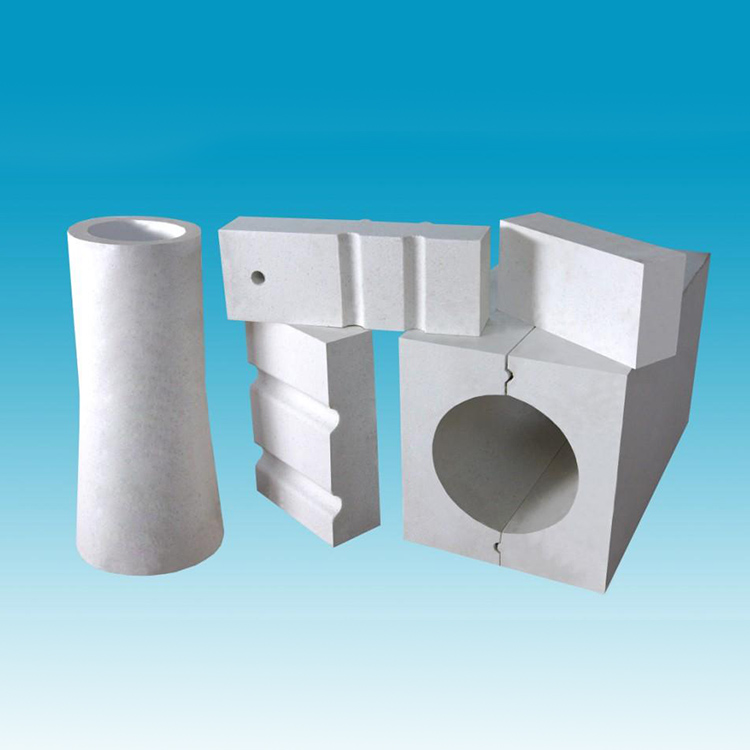

Mullite insulation bricks are known for their excellent thermal insulation properties. They can effectively reduce heat loss in kilns, which is a significant factor in energy conservation. With a high refractoriness, often exceeding 1700°C, these bricks can withstand extremely high temperatures without significant deformation. Their high - strength composition ensures the structural integrity of the kiln lining, even under harsh operating conditions.

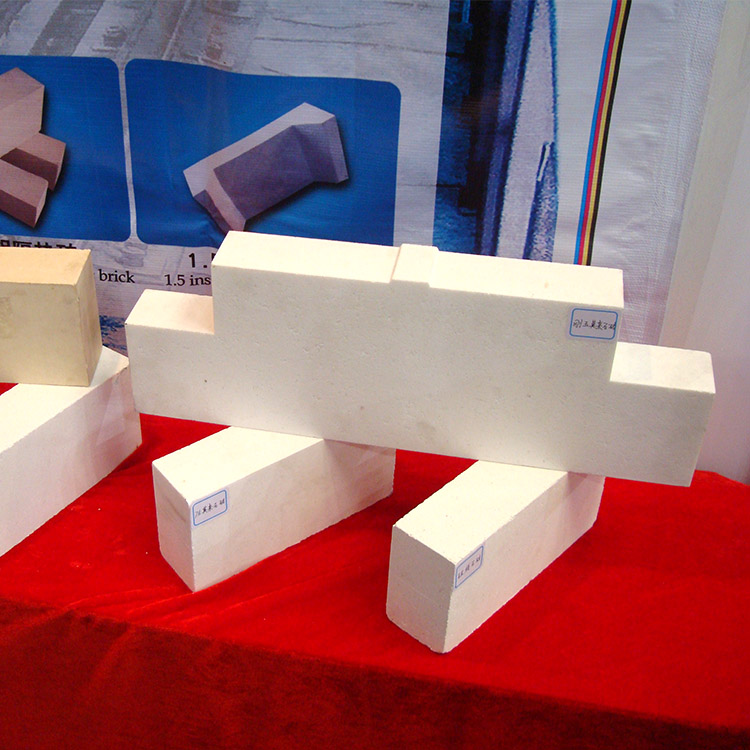

Moreover, the precise dimensions of mullite insulation bricks are a key advantage. This allows for accurate and rapid masonry, reducing the time required for installation. In addition, the consistent size helps to minimize the amount of refractory mortar used, saving both material costs and labor time.

Mullite insulation bricks have demonstrated outstanding performance in a variety of industrial kilns. For example, in electric porcelain drawer kilns, they provide excellent thermal insulation, allowing for more energy - efficient firing processes. In oil cracking kilns, their high - temperature resistance ensures stable operation and reduces the frequency of maintenance due to brick damage.

In ceramic roller kilns, the precise dimensions of mullite insulation bricks enable smooth and efficient masonry, contributing to the overall stability of the kiln structure. The use of these bricks has been shown to increase the productivity of the kilns by up to 20% and reduce energy consumption by 15 - 20% compared to traditional refractory materials.

The masonry process of mullite insulation bricks involves several key steps. Firstly, proper preparation is essential. This includes cleaning the base surface, ensuring its flatness and strength. The dimensions of the bricks need to be carefully checked to ensure they meet the design requirements. Any bricks with significant dimensional deviations should be rejected.

The masonry sequence is also crucial. Usually, the bricks are laid in a staggered pattern to enhance the structural stability of the kiln lining. The choice of refractory mortar is another important factor. A high - quality mortar with good adhesion and heat resistance should be selected. After masonry, proper curing management is necessary to ensure the full development of the mortar's strength.

To ensure the success of the masonry project, some key technical points need to be emphasized. For example, the joint width between bricks should be controlled within a reasonable range (usually 2 - 3mm) to ensure uniform heat transfer and structural strength. In case of problems such as brick cracking or uneven masonry, timely solutions should be taken.

If cracking occurs, it may be due to improper mortar formulation or rapid temperature changes. Replacing the mortar or adjusting the curing process can often solve these problems. Uneven masonry can be corrected by re - checking the base surface and readjusting the brick positions.

In conclusion, mullite insulation bricks offer a comprehensive solution for overseas kiln projects. Their excellent material properties, combined with proper masonry techniques, can significantly reduce maintenance costs, save energy, and improve the overall performance of industrial kilns. For more information on our mullite insulation bricks and professional technical support, click here.