In the era of global energy conservation and environmental protection, high - temperature kilns, as important equipment in many industries, are facing the challenge of high energy consumption. High - strength refractory clay insulation bricks have emerged as a key solution to address this issue, offering significant potential for energy savings and performance improvement in high - temperature kilns.

High - temperature kilns are widely used in industries such as metallurgy, ceramics, and glass. However, they often consume large amounts of energy. According to statistics, in some traditional high - temperature kilns, energy consumption can account for up to 30% - 50% of the total production cost. The main reason for this high energy consumption is the heat loss through the kiln lining. Therefore, improving the insulation performance of the kiln lining is crucial for energy conservation.

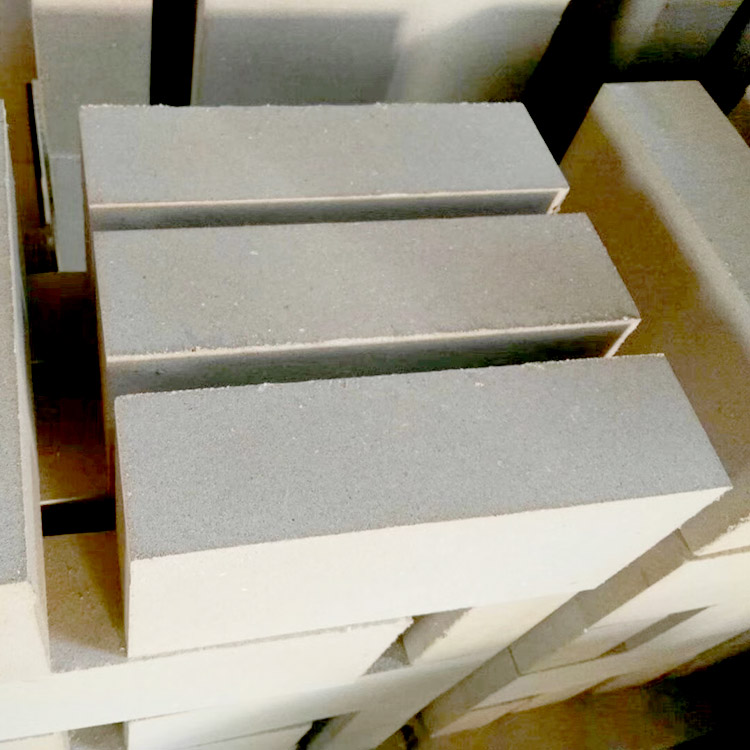

The low thermal conductivity of refractory insulation bricks is one of their most important features. The thermal conductivity of these bricks can be as low as 0.1 - 0.3 W/(m·K), which is significantly lower than that of traditional refractory materials. This low thermal conductivity effectively reduces the heat transfer rate, thereby reducing heat loss from the kiln.

In high - temperature kilns, the lining is often subjected to rapid temperature changes. High - strength refractory clay insulation bricks have excellent thermal shock resistance, which can withstand more than 50 - 100 thermal shock cycles without significant damage. This property ensures the stability of the kiln lining during temperature fluctuations.

The thermal conduction of refractory insulation bricks is mainly blocked through two mechanisms. Firstly, the unique pore structure of the bricks traps a large amount of air, and air is a poor conductor of heat. Secondly, the chemical composition of the bricks can absorb and scatter heat, further reducing the heat transfer rate.

During the construction process, the control of masonry gaps is crucial. The width of the gaps should be controlled within 1 - 2 mm. A smaller gap can reduce heat leakage through the gaps.

Expansion joints need to be set at appropriate intervals to accommodate the expansion of the bricks during heating. The width of the expansion joints is usually 5 - 10 mm, and they should be filled with appropriate expansion materials.

Inter - layer sealing is also an important part of the construction. High - temperature resistant sealants can be used to seal the gaps between layers, preventing heat from bypassing the insulation layer.

In a ceramic factory, after replacing the traditional refractory materials with high - strength refractory clay insulation bricks, the energy consumption of the kiln was reduced by 20% - 30%. At the same time, the service life of the kiln lining was extended from about 1 - 2 years to more than 3 - 5 years, greatly reducing the maintenance cost and production interruption.

In conclusion, high - strength refractory clay insulation bricks play a key role in the energy conservation of high - temperature kilns. Through scientific design and proper construction, these bricks can effectively reduce energy consumption, extend the service life of the kiln lining, and promote the green and low - carbon transformation of enterprises. If you are interested in learning more about our high - performance refractory insulation bricks and getting a customized energy - saving solution, please click here.