In the chemical industry, furnace design is a critical process that often faces challenges due to improper selection of refractory materials. These mistakes can lead to high energy consumption, short equipment lifespan, and even safety hazards. This article aims to provide a comprehensive guide to help engineers avoid these pitfalls and make informed decisions when selecting refractory materials for chemical furnaces.

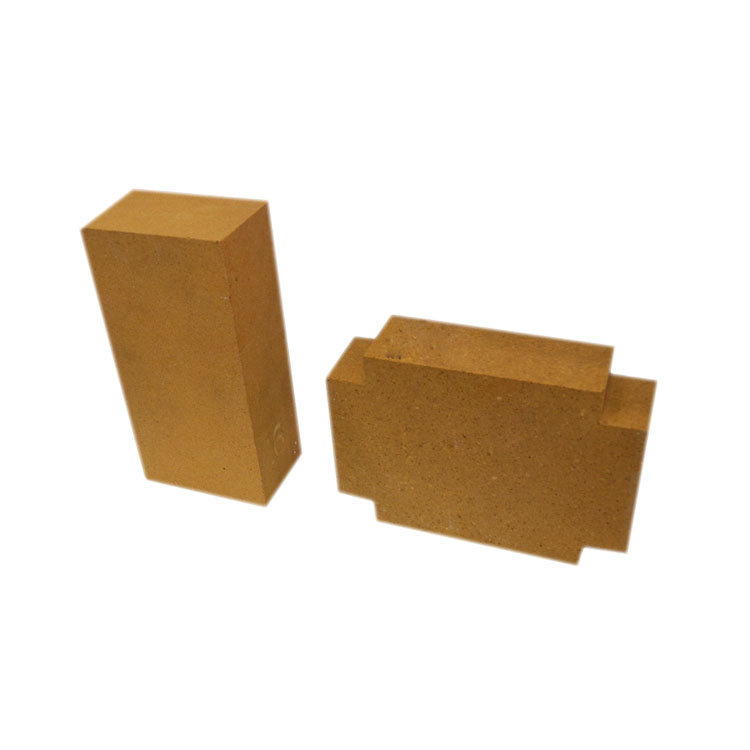

When it comes to refractory materials for chemical furnaces operating below 1350°C, several key performance indicators need to be considered. High - strength refractory clay insulating bricks stand out with their low thermal conductivity, excellent thermal shock resistance, and minimal re - heating linear change.

Thermal conductivity is a crucial factor as it directly affects energy efficiency. High - strength refractory clay insulating bricks typically have a thermal conductivity of around 0.2 - 0.3 W/(m·K) at 1000°C, which is significantly lower than some other common materials. This low thermal conductivity helps to reduce heat loss from the furnace, resulting in lower energy consumption.

Thermal shock resistance is equally important, especially in furnaces that experience frequent start - stop cycles or significant temperature fluctuations. High - strength refractory clay insulating bricks can withstand rapid temperature changes without cracking or spalling. They can endure temperature differences of up to 800 - 900°C without significant damage, ensuring the long - term stability of the furnace lining.

The re - heating linear change of these bricks is also extremely small, usually less than 0.2% after being heated at 1300°C for 2 hours. This means that the shape and size of the bricks remain stable during long - term use, preventing gaps and cracks in the furnace lining that could lead to heat leakage and reduced equipment performance.

To better understand the advantages of high - strength refractory clay insulating bricks, let's compare them with other common refractory materials such as high - alumina bricks and ordinary clay bricks.

| Material | Thermal Conductivity at 1000°C (W/(m·K)) | Thermal Shock Resistance (Temperature Difference) | Re - heating Linear Change at 1300°C for 2h |

|---|---|---|---|

| High - strength refractory clay insulating bricks | 0.2 - 0.3 | 800 - 900°C | <0.2% |

| High - alumina bricks | 0.4 - 0.6 | 500 - 600°C | 0.3 - 0.5% |

| Ordinary clay bricks | 0.5 - 0.7 | 300 - 400°C | 0.5 - 0.8% |

As shown in the table, high - strength refractory clay insulating bricks have a clear edge in terms of thermal conductivity, thermal shock resistance, and re - heating linear change. High - alumina bricks, although having relatively high refractoriness, have higher thermal conductivity and lower thermal shock resistance, which may not be suitable for furnaces with frequent temperature changes. Ordinary clay bricks, on the other hand, have even poorer performance in these aspects.

In chemical furnaces, different working conditions require different refractory materials. For furnaces that operate under relatively stable temperature conditions with occasional small temperature fluctuations, high - alumina bricks may be a viable option. However, for furnaces that experience frequent start - stop cycles, such as those in some batch - processing chemical plants, high - strength refractory clay insulating bricks are the preferred choice.

For example, in a chemical plant where a furnace is used for intermittent production, the furnace lining made of high - strength refractory clay insulating bricks has shown excellent performance. After several years of operation, the lining remains intact, with no signs of significant damage or cracking. In contrast, a nearby furnace using ordinary clay bricks had to be repaired multiple times due to cracking and spalling, resulting in increased maintenance costs and production downtime.

One of the most common misconceptions in refractory material selection is focusing solely on price while ignoring material stability. Some engineers may choose cheaper materials without fully considering their long - term performance. For example, they may opt for ordinary clay bricks because of their lower upfront cost, but in the long run, the frequent repairs and replacements due to poor performance end up costing more.

Another misconception is relying too much on theoretical data and not enough on actual engineering experience. Theoretical data can provide a general idea of material performance, but in real - world applications, factors such as installation quality, operating conditions, and maintenance also play important roles. To address these issues, engineers should consult with experienced refractory material suppliers and refer to actual project cases.

"In our project, we initially selected high - alumina bricks based on theoretical calculations. However, after a few months of operation, we noticed significant cracking in the furnace lining. After consulting with the supplier and switching to high - strength refractory clay insulating bricks, the problem was solved, and the furnace has been running smoothly ever since." - An engineer from a chemical plant

Selecting the right refractory material is crucial for the energy efficiency, safety, and long - term performance of chemical furnaces. High - strength refractory clay insulating bricks offer significant advantages in terms of thermal conductivity, thermal shock resistance, and re - heating linear change, especially in environments with frequent start - stop cycles or large temperature fluctuations.

To help you make more informed decisions, we offer detailed technical parameters and a comprehensive selection reference manual. Click here to learn more about the technical parameters and obtain the selection reference manual.